– Industry –

Our modern infrastructure enables us to manufacture a wide range of cross-sections for various industrial applications: simple standard rails for the electrical industry, complex cross-sections for the machine industry, highly decorative profiles for the furniture and lighting industry or fully machined mechanical engineering components. We use our experience and competence to manufacture the most demanding profiles with the narrowest tolerances in top quality.

Product Portfolio

Profiles for general mechanical engineering

Heat sink profiles

Housing profiles

Design profiles for the furniture and lighting industry

Profiles for medical technology

Special profiles for the textile industry

Our Value Chain

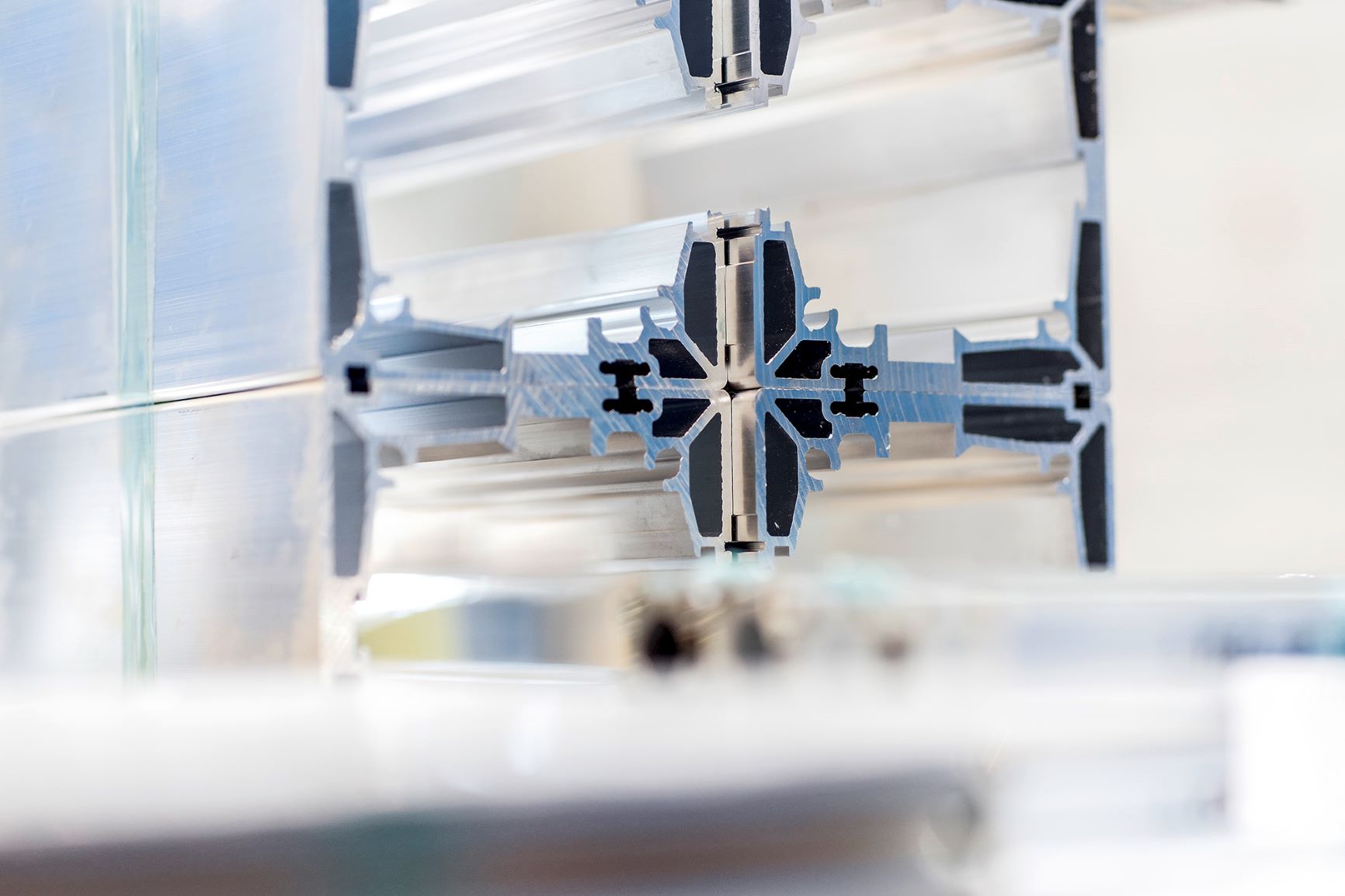

We offer solutions for customer-specific surface requirements, in-house colourless anodising up to 13 m in length (standard), internal anodising up to 6 m in length with a layer thickness of up to 25 micrometres and coating hardness of up to HV 420. Powder coating in all common RAL and NCS colour shades is possible.

We handle everything cohesively from the final process steps all the way up to the finished product. We work closely with our customers to determine the most comprehensive scope of testing based on the quality requirements.

We can rely on years of experience with renowned customers, from prototyping to series implementation. We support our clients in the production-oriented design of profiles and components.

We provide consultation to our customers to help them select suitable alloys that meet their special requirements. For example, we advise them on the strength, corrosion resistance and surface properties for design surfaces, so they can always pick the highest quality at the lowest price.

We offer all common alloy types (3xxx/5xxx/6xxx) for the industrial sector. Thanks to our extensive experience in special mechanical engineering, we are able to implement the narrowest tolerances (e.g. bore tolerance H11) and surface requirements (roughness) in a product-oriented and cost-effective manner.

Our locations feature state-of-the-art 3 to 5 axis machining centres that meet the high tolerance requirements of our customers. Long part machining is possible up to 6 m (CNC machining in the 1/100 range).

We know the market

Through our partnership with many well-known international manufacturers, we understand the market needs very well and are able to react quickly and efficiently to changes.

Our know-how comes into play in various areas. Typical application areas are profiles for general and specialised mechanical engineering, heat sink profiles, profiles with electrical conductivity as well as products with the highest optical requirements for the furniture and design industry.

Know-how in profile production

Selecting the right material as well as skilful processing ensure that the finished profile meets the customer’s requirements. With long-standing experience and technical expertise, we meet the highest requirements in terms of functionality and precision for all products for industrial applications.

We support our customers right from the product development phase and advise them on the best technical and cost-effective implementation of the project.

With our extrusion presses, we can produce wraps from 10 mm to 420 mm and profile weights from 0.1 kg/m to 30 kg/m. Narrow cross-section tolerances, shape and position tolerances as well as bore tolerances up to H11 are no problem for us.

From semi-finished product to assembly – One-Stop Shop Alu Menziken

Thanks to our complete value chain, we are a true one-stop shop. From press-finished profiles without further processing to ready-to-install assemblies, all options are open to our customers. Precise high-performance saws and state-of-the-art CNC machining and long-bed centres are utilised for all the work steps up to the customised finished product with accuracies in the 1/100 range.

Any type of packaging based on individual requests can be provided, including customer-specific packaging units or labelled packaging.

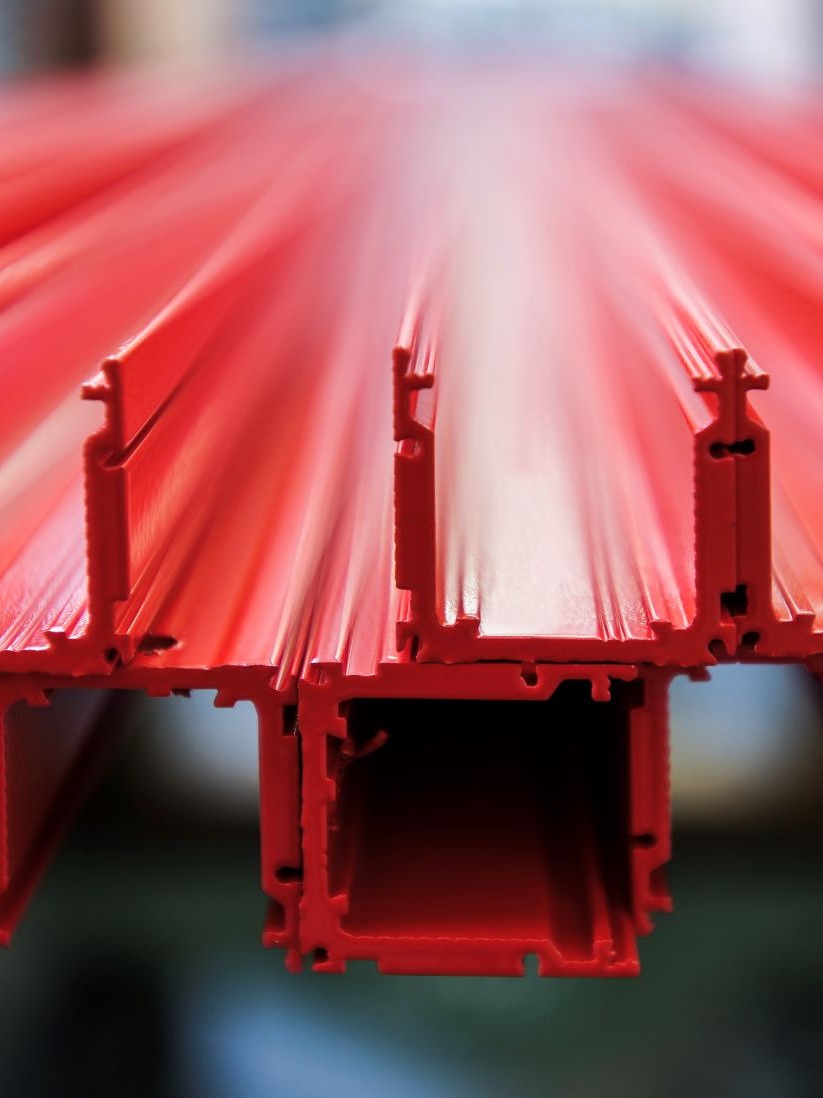

We treat surfaces more than just superficially

The right surface finish gives a product a decorative appearance and improves its durability and corrosion resistance.

We specialise in colourless anodising (even for excess lengths up to 13 m), vertical powder coating up to 7.5 m as well as brushed and ground surfaces.

For other coating technologies, we collaborate with long-time customer-approved partners.

Contact

Urs Nussbaumer

KAM Industry and Construction Switzerland

hef.ahffonhzre@nyh-zramvxra.pbz

+41 79 960 0286

+41 62 765 2242

Marc Reifenstein

KAM Industry and Construction Germany North

znep.ervsrafgrva@nyh-zramvxra.pbz

+49 175 947 4533

Wolfgang Schumpp

KAM Industry and Construction Germany South

and Austria

jbystnat.fpuhzcc@nyh-zramvxra.pbz

+49 1511 7569759

+49 7741 9656339