– Extrusion –

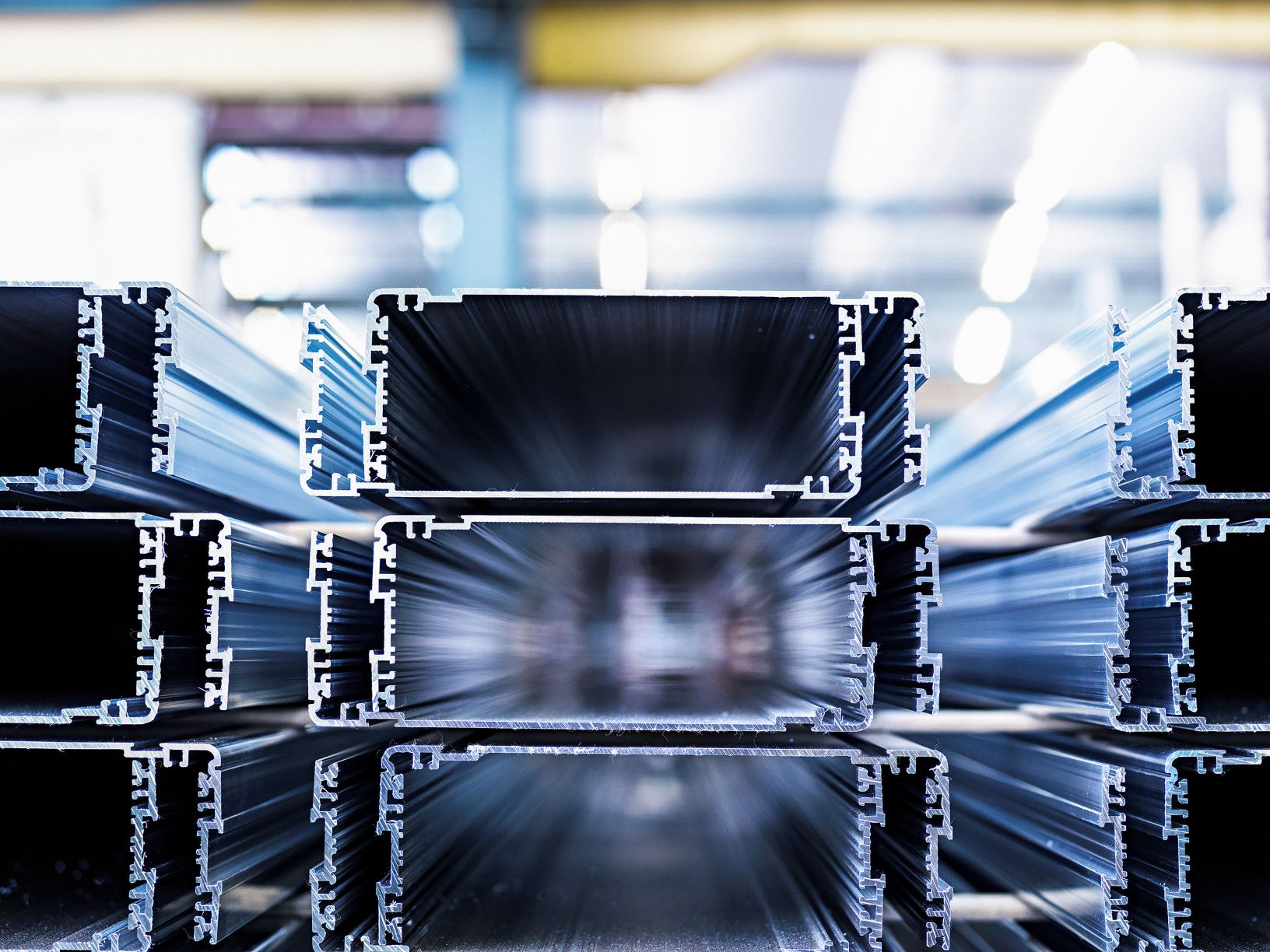

Highest precision for demanding profiles

In our state-of-the-art aluminium extrusion plants, we produce profiles with complex cross-sections, the narrowest manufacturing tolerances and high-quality surfaces. We are flexible and produce the most demanding profiles and tubes for applications in the automotive, aerospace, railway, pneumatic, construction and industrial sectors with consistently high quality.

Technical know-how in casting and extrusion

Alu Menziken is your technological partner for high-quality extruded products that meet the highest requirements in terms of alloy properties, tolerances and surfaces.

In addition to a wide range of standard materials, we also develop and process customer-specific alloys. Especially in the field of crash alloys, we work with renowned OEMs in the German automotive industry and jointly define tailor-made materials for their customer requirements.

Our high-tech extrusion lines are among the most modern in Europe and are designed for processing 3xxx, 4xxx, 5xxx, 6xxx and 7xxx aluminium alloys with an annual capacity of approx. 30,000 MT.

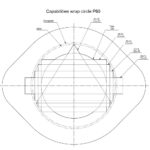

Due to the comprehensive product range of wrap options (10 mm to 420 mm) and profile weights (from 0.1 kg/m to 30 kg/m), we cover a large part of the market demand for profile geometries.

Focus on the customer

Knowledge of our customers’ requirements and processes leads to great collaboration and the best possible customer satisfaction.

We work closely with our customers during the project phase and advise them on selecting the right alloys; or we develop customised solutions that precisely meet the desired product requirements. Moreover, we share our expertise on the best possible geometric design of the profile cross-sections to achieve the best possible technical and commercial result.

Our comprehensive understanding of our customers coupled with years of experience enables a smooth process along the entire value chain.

Step by step to the high-quality extrusion press product

Five extrusion presses with a press force between 11 and 60 MN are available for the production of our high-quality aluminium profiles. All presses use the direct extrusion process; one press is designed to produce seamless tubes.

The starting material of each profile is the aluminium billet, which is heated to a temperature of approx. 500 °C at the press and shaped into the desired geometry by a die. The profile, which can be up to 63 m long, is cooled, stretched and shortened to a manageable length of approx. 6 m on the press.

The subsequent heat treatment in special furnaces at approx. 180 °C gives the profile the required strength. Extensive quality tests validate the perfect quality of the products.

Upon request, we can offer a wide range of options for further processing of the profiles, from mechanical processing and surface finishing to the production of ready-to-install components.

Our profiles are used in the automotive, aerospace, railway, pneumatic, construction and industrial sectors.

|

Press

|

Press force

|

Wrap

|

Profile weight

|

Recipient

|

|---|---|---|---|---|

|

P11

|

11 MN

|

150 mm

|

0,1 – 1,5 kg/m

|

Ø 5“

|

|

P15

|

15 MN

|

140 mm

|

0,6 – 3,5 kg/m

|

Ø 7“

|

|

P16

|

16 MN

|

160 mm

|

0,6 – 2,5 kg/m

|

Ø 7“

|

|

P35

|

35 MN

|

280 mm

|

1,5 – 9,5 kg/m

|

Ø 9“

|

|

P60

|

60 MN

|

440 mm

|

2,5 – 30 kg/m

|

Ø 12“

|

Possible delivery length 2–13 m, tolerances ± 0.02–0.15 mm

Manufacturing possibilities of our presses

Click to enlarge …