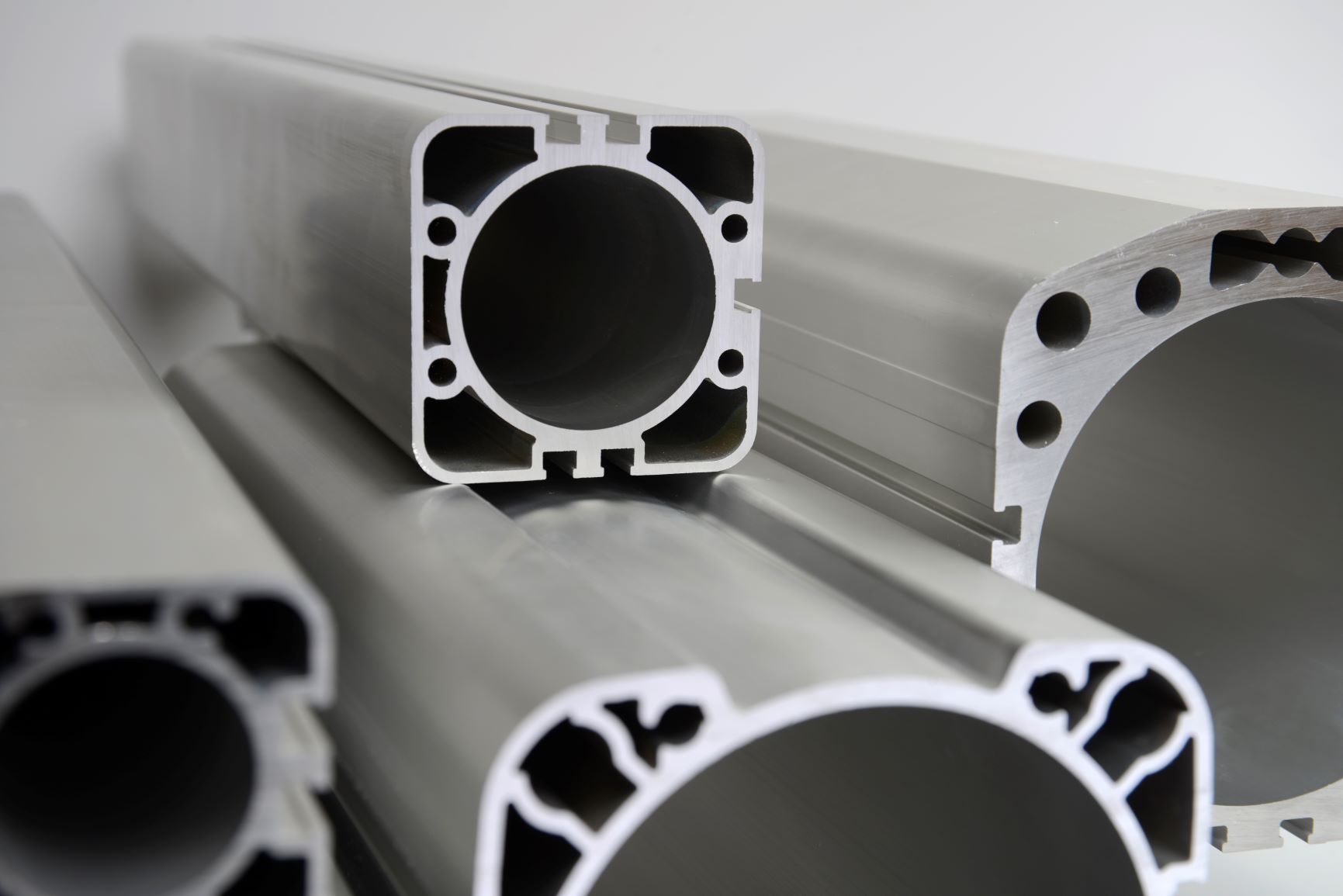

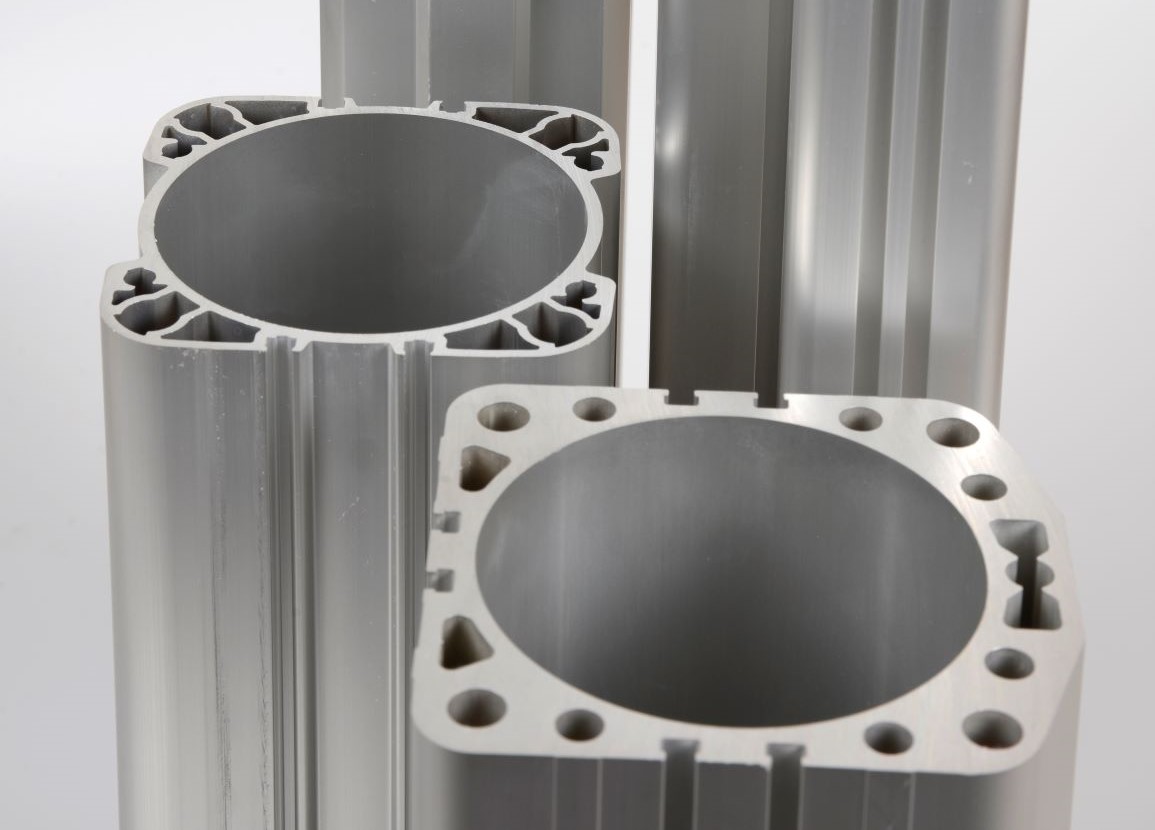

– Pneumatics –

When it comes to pneumatics, there is hardly any other aluminium specialist who comes close to our competence and know-how in this field. Years of experience in the production of aluminium cylinders with precise inner diameter tolerances and top quality of the inner tube surface make us one of the leading manufacturers for pneumatic applications in the automation industry, in plant engineering, for measuring equipment as well as medical applications.

Our Value Chain

We offer solutions for customer-specific surface requirements, in-house colourless anodising up to 13 m in length (standard), internal anodising up to 6 m in length with a layer thickness of up to 25 micrometres and coating hardness of up to HV 420. Powder coating in all common RAL and NCS colour shades is possible.

We handle everything cohesively from the final process steps all the way up to the finished product. We work closely with our customers to determine the most comprehensive scope of testing based on the quality requirements.

We can rely on years of experience with renowned customers, from prototyping to series implementation. We support our clients in the production-oriented design of profiles and components.

We provide consultation to our customers to help them select suitable alloys that meet their special requirements. For example, we advise them on the strength, corrosion resistance and surface properties for design surfaces, so they can always pick the highest quality at the lowest price.

In addition to the 6xxx alloys commonly used in the pneumatic sector, we are also happy to check the feasibility of other alloys (3xxx or 5xxx) upon request. Thanks to our extensive experience in special mechanical engineering, we are able to implement the narrowest tolerances (e.g. bore tolerance H11) and surface requirements (roughness) in a product-oriented and cost-effective manner.

Our locations feature state-of-the-art 3 to 5 axis machining centres that meet the high tolerance requirements of our customers. Long part machining is possible up to 6 m (CNC machining in the 1/100 range).

We will gladly advise you

Choosing the right alloy and defining optimum specifications can be instrumental for the success of a project. Together with our customers, we develop perfect solutions for unique challenges and provide support in optimising profile cross-sections.

We treat surfaces more than just superficially

An anodised surface prevents wear and ensures perfect functionality.

Our standardised anodising process is optimally adapted to the requirements of the market. We anodise colourlessly on the inside and outside at a max. coating hardness of HV 420 and a layer thickness of 15–25 μm (with standard anodising). The decorative aspect of the aluminium is retained.

For a particularly high-quality surface, the material can be brushed before anodising upon request.

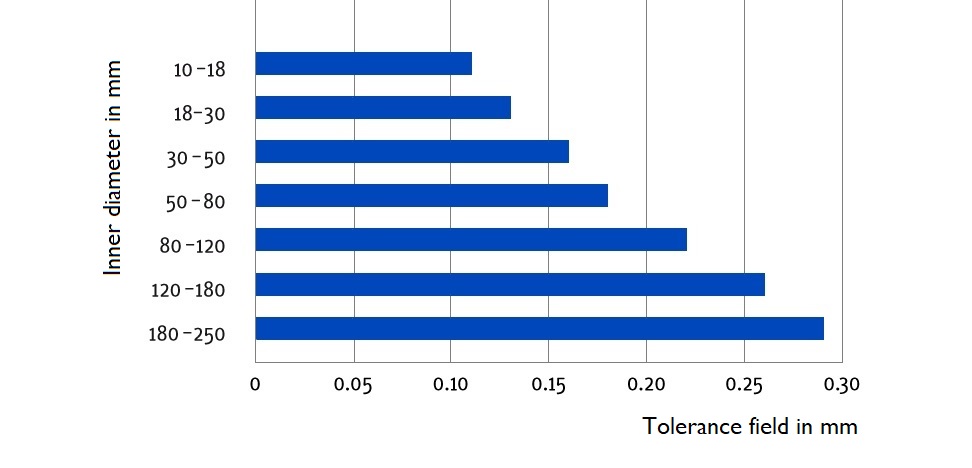

Narrowest tolerances and smallest roughness are our core strength

Extremely low tolerances and roughness in the cylinder bore hole are the most important characteristics of a high-quality pneumatic profile. Narrow cross-section tolerances, shape and position tolerances as well as bore tolerances up to H11 are no problem for us. We achieve this level of perfection without additional cost-intensive post-processing such as honing. The tolerances are continuously monitored and documented during the manufacturing process. Necessary corrections can be made at any point in the manufacturing process.