– Aerospace –

The aerospace industry has high demands on weight, strength and surface quality. With more than 60 years of experience in this industry, we have the necessary production know-how for high-precision aluminium extruded products and lightweight components with excellent surface finish. Well-known manufacturers and suppliers value our expertise in the project planning and implementation of even complex projects.

Product Portfolio

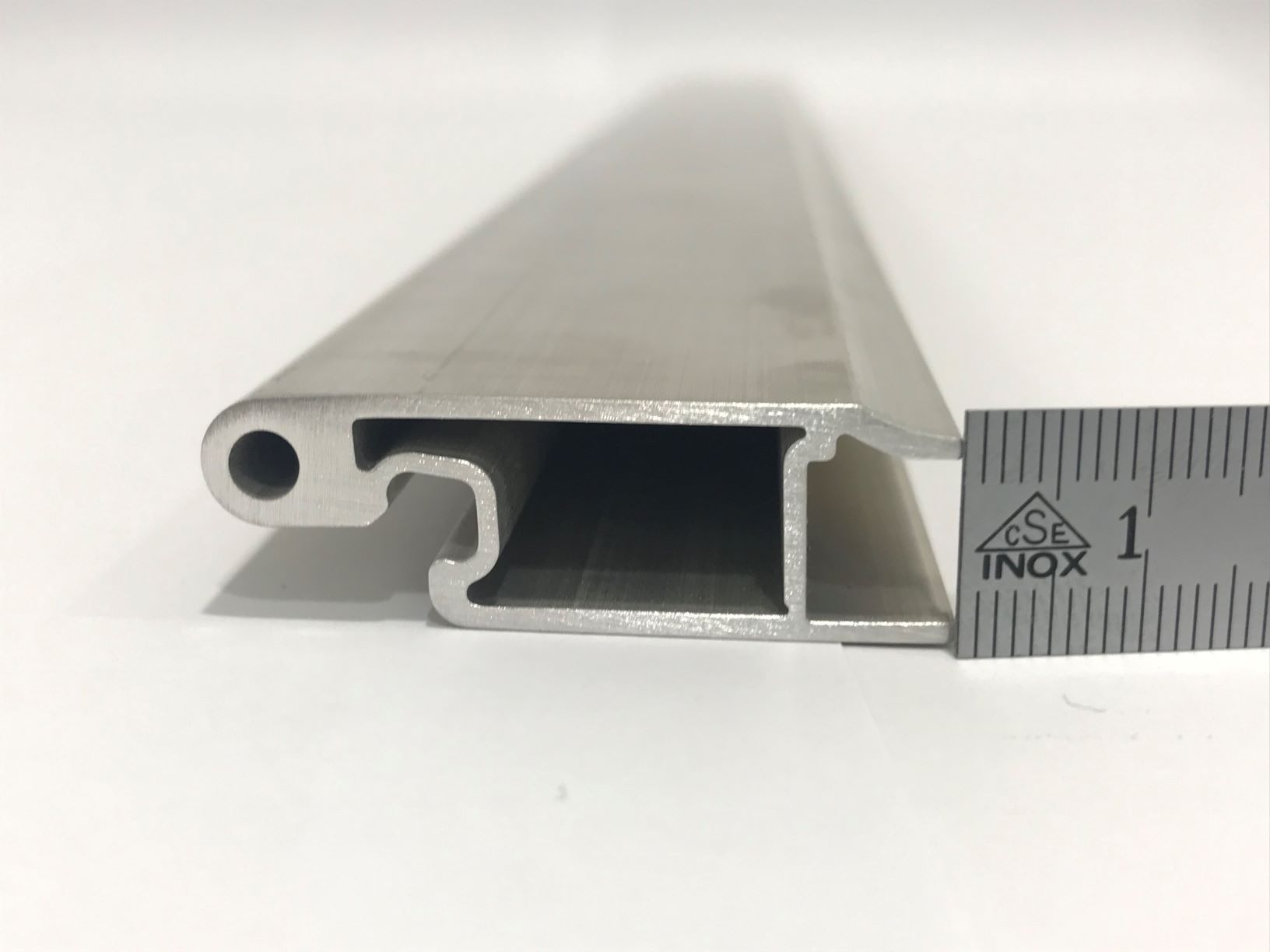

Lightweight seat structure and systems

Components for cabin interiors, such as light bars, overhead stowage compartments, PSU rails, galleys, edge protectors, cable ducts, brackets

Our Value Chain

With long-standing experience in profile bending processes, we can shape your component based on your specifications.

Our core business includes state-of-the-art welding processes like MIG CMT and cutting-edge laser hybrid welding technology.

Other joining processes such as self-piercing riveting are also possible

We handle everything cohesively from the final process steps all the way up to the finished complex product with corresponding validation processes. We work closely with our customers to determine the most comprehensive scope of testing based on the highest quality requirements.

We can rely on years of experience with renowned OEMs and first tier suppliers, from individual production to series implementation. We support our clients in the production-oriented design of their components.

We advise our customers on the selection of suitable alloys and develop customised alloys. Defined homogenisation processes ensure the desired properties, which can also be tested using ultrasound methods.

We offer all common soft alloy types in the aerospace sector.

Our locations feature state-of-the-art 3 to 5 axis machining centres that meet the high tolerance requirements of our customers. For optically perfect visible surfaces, the components are ground on grinding robots.

We offer solutions for customer-specific surface requirements from washing to coating technologies with long-term customer-approved partners.

One-Stop-Shop Alu Menziken

60 years of experience in the aerospace industry have made us a reliable manufacturer of high-precision aluminium extrusion press products. Our know-how combined with the technological capacities enable us to offer highly complex components along a complete value chain.

We provide our customers with support when it comes to the production-oriented design of customer projects and advise them on the best technical and cost-effective implementation. With a comprehensive portfolio of services including billet casting, extrusion, machining, forming, surface finishing and assembly, we cover every step in the manufacturing process.

Potentials in lightweight construction – Successful processing of magnesium alloys

‘Light, lighter, lightest’ is the motto in the automotive and aerospace industries. The current development in these industries leads to an ever increasing demand for lightweight materials.

Using a magnesium alloy certified for aviation, the project team produced thin-walled hollow profiles for applications in the interior of aircraft cabins.

AS 9100 certified

Alu Menziken supplies manufacturers and suppliers of the aviation industry worldwide with high-quality extrusion press products. The focus is on the high requirements for product quality and process reliability. AS 9100 is a globally recognised standard in the aerospace industry. Certification for the stringent AS 9100 standards is proof that our production and operational processes in the areas of development, production and maintenance are stable and reliable.

Contact

Christian Plangger

KAM & PM Aerospace

KAM Railway

puevfgvna.cynattre@nyh-zramvxra.pbz

+43 664 61 48 812

+43 7722 887 7534