– Railway –

The global trend towards expansion of railway transportation is leading to a growing demand for high-quality aluminium products. The all-rounder among metals fulfils the requirements for durability, workability, lightness, strength and appearance. With extensive know-how and flexibility, we are the reliable partner when it comes to stable structural components or visible parts with a high-quality surface.

Product Portfolio

Car body structural components

Profiles for the car interior, e.g. luggage racks, foot boards, edge protectors and floor profiles, partition profiles, border profiles (windows), frame profiles

Our Value Chain

We offer solutions for customer-specific surface requirements in-house or with long-term customer-approved partners. Colourless anodising up to 13 m and powder coating in all common RAL and NCS colours in our factory ensure a perfect surface finish.

With long-standing experience in profile bending processes, we can shape your component based on your specifications.

Our core business includes state-of-the-art welding processes like MIG CMT and cutting-edge laser hybrid welding technology. Laser hybrid technology in particular is perfectly suited for large components like the ones used in e-mobility.

Other joining processes such as self-piercing riveting are also possible.

We handle everything cohesively from the final assembly up to the ready-to-install product with corresponding quality testing. Together with our customers, we define the desired scope of testing and implement it with the utmost precision and care.

We can rely on years of experience with renowned customers, from prototyping to series implementation. We support our clients throughout the entire production chain and work out a cost-optimised solution together.

We provide consultation to our customers to help them select suitable alloys that meet their special requirements. For example, we advise them on the strength, corrosion resistance and surface properties for design surfaces, so they can always pick the highest quality at the lowest price.

We offer all common alloy types for the railway sector. Thanks to our extensive experience in manufacturing high-quality aluminium products, we are able to meet the narrowest tolerances with the highest surface requirements.

Our locations feature state-of-the-art 3 to 5 axis machining centres that meet the high tolerance requirements of our customers. Long part machining is possible up to 6 m (CNC machining in the 1/100 range).

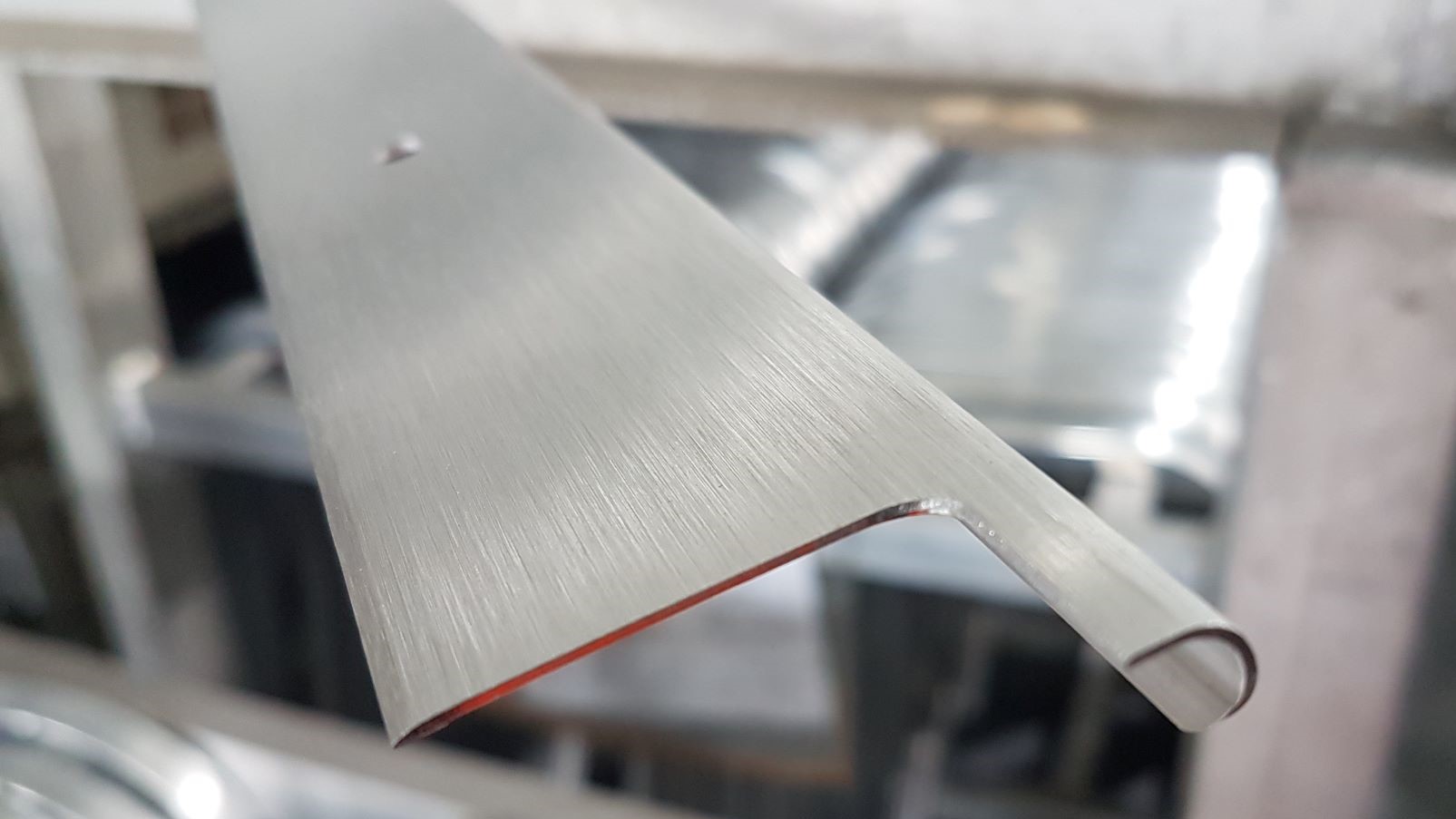

With our fully automated grinding robots we can produce high-quality brushed and ground surfaces with a consistent quality.

One-Stop Shop – Everything under one roof

High-precision profiles, CNC processing, surface finishing, component assembly – we offer railway vehicle manufacturers a comprehensive portfolio that meets all requirements. Our customers already benefit from our know-how during the project support phase, and we provide advice on the best technical and cost-effective implementation of customer projects. Our group has the capacity to handle large volume orders, but we are equally proud of our flat hierarchies and high flexibility to accommodate small quantities.

Surface finish

The right surface finish preserves or improves the functionality and visual appearance of a product. In our factory we offer various surface finishing options. Above all, colourless anodising is one of our key specialities. Profiles up to 13 m in length are treated with the appropriate surface finish with a layer thickness of up to 25 µm and a coating hardness of up to HV 420.

With our fully automated grinding robots we can produce high-quality brushed and ground surfaces with a consistent quality.

Additional options are powder coating and brushing. For other coating technologies, we work with long-term customer-approved partners.

Contact

Christian Plangger

KAM Railway

KAM & PM Aerospace

puevfgvna.cynattre@nyh-zramvxra.pbz

+43 664 61 48 812

+43 7722 887 7534